CPD and OPITO accredited

Buy and assign to

multiple learners

Instant access

via email link

Instant certificate

via email

Further Information - Authorised Gas Tester Training Course - OPITO approved

Description

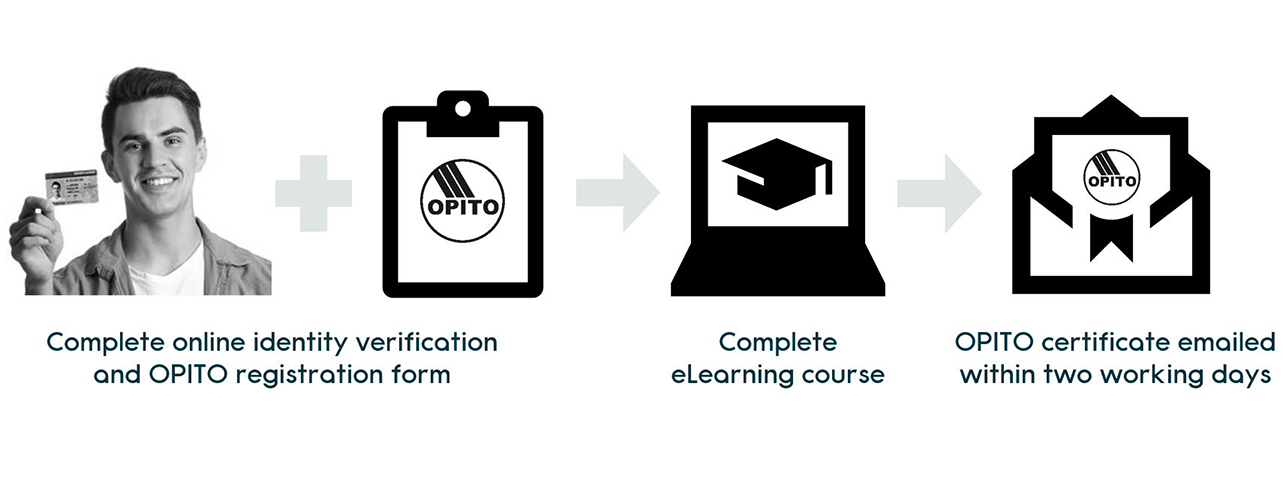

This OPITO-approved course can be completed online with identity verification.

Before you can access the course, you will be asked to complete an identity verification check followed by an OPITO registration form. The course cannot be accessed until both steps are completed.

For the identity verification check, you will need a picture ID, such as a passport or driving license, and a smartphone.

On completion of the course, you will automatically receive a Mintra certificate and this will then be replaced with the OPITO - approved certificate usually within two business days.

Who is the course for?

This course contains the underpinning knowledge for Authorised Gas Testing required for those involved in carrying out tests for oxygen and for flammable and toxic gases prior to hot work or work in a confined space, and for those involved in performing safety watch duties for hot work activities.

Is previous experience required?

It is expected that as a participant in this course, you will have received formal training in gas testing and that you hold suitable qualifications.

How will the course benefit me?

The risk of incidents involving gas occurs across the international oil and gas industry, particularly when working in confined spaces or during hot work. This course will give you a basic understanding of gas hazards and how these can be mitigated by testing and other control measures.

The knowledge gained in this course will help you understand how, when and where to carry out the necessary gas tests prior to confined space entry activities.

How will the course benefit my company?

By correctly ensuring that atmospheres are safe for hot work or work activities in confined spaces, you contribute to the safety of the asset, your fellow workers and yourself. A reduction in incidents means a safer working environment for everyone.

What standards are referenced in the course?

This course is based on the OPITO Approved Authorised Gas Tester. Standard codes 9240 and 9242 (Digital Delivery)

Health and Safety at Work Act

CoSHH

PFEER

Management of Health and Safety at Work Regulations

EH40 Workplace Exposure Limits (WELs)

Confined Space Regulations

Is there an assessment?

Once you have completed the course, you will be asked questions to check your knowledge and understanding. These are based on the course elements and have a pass mark of 100%

Learning Objectives

Section 1: Introduction

- Define the structure of the course

- Identify the role of the Gas Tester

- Identify the consequences of not carrying out the role correctly

Section 2: Hazards Associated with Gases and Vapours

- Describe the organisational and statutory requirements in relation to gas testing and the requirements for safe systems of work

- Identify examples of the various gases encountered in the Oil and Gas Industry

- Define the relative densities of each gas and where the Gas Tester would normally expect to locate them

- Discuss how the movement of gases can be affected by plant configuration, the effect of ‘fin-fan’ coolers, and wind direction and speed

Section 3: Flammable Atmospheres

- Describe how flammable atmospheres can be created

- Illustrate the formation of gas plumes and the effects of turbulence

- Define LEL, the explosive envelope and UEL

- Identify the various alarm settings and the relationship between the % LEL and % by volume

Section 4: Fire and Explosions

- Explain the Fire Triangle

- Identify the need to remove fuel sources to prevent fire and explosions

- Illustrate the effects of explosions and overpressure

- Describe the effects of pool fires and jet fires

Section 5: Toxic Atmospheres

- Describe the human respiratory system

- Describe the effects of toxic gases on the human body

Section 6: Oxygen Deficiency and Oxygen Enrichment

- Describe the effects of oxygen depletion on the human body

- Describe the effects of oxygen enrichment on the human body

- Describe the risk of flash fires due to oxygen enrichment

Section 7: Hazards of Confined Spaces

- Define what is meant by a confined space

- Describe the possible risks that may be encountered during gas testing of confined space

Section 8: Gas Monitors

- Describe, and explain the general operation of, a generic four channel gas monitor

- Describe the standard checks to be carried out prior to use of the gas monitor

- Describe the older technology gas monitors and the restrictions in their use

Section 9: Using Gas for Fire Watcher Duties

- Describe the use of the gas detector during hot work operations and the role of the Fire Watcher

- Explain the location of the Fire Watcher, the portable Gas Monitor and the actions to take if the alarm is sounded

- Describe the sentinel type gas monitor, its required location during hot work, and the alarm response actions

Section 10: Gas Testing for Hot Work

- Illustrate the correct use of the gas testing equipment and probe for testing prior to hot work

- Describe how consideration should be given to the wind direction and the effect of hot metal and sparks on adjacent areas

- Identify the areas and equipment that should be tested

Section 11: Using Gas Testing and Gas Leak

- Explain how to plan the test

- Describe the technique in using the probe to carry out the test

Illustrate the potential risk to the Gas Tester and the risk mitigation measures that should be considered

Section 12: Gas Testing for Confined Space Prior to Entry

- Explain how to plan the gas testing of a confined space

- Describe how some confined space configurations will require more than one test area

- Describe the chimney effect of tall process columns and the technique in testing this type of equipment

- Describe the use of visual inspections prior to testing to give an indication of the possibility of toxic gases or oxygen depletion

- Identify the possible risks during gas testing of confined spaces and the risk mitigation methods

Section 13: Gas Testing during Purging Operations

- Describe the technique to be used when testing for levels of hydrocarbons during purging operations

- Describe the technique to be used when testing for levels of oxygen prior to the reintroduction of hydrocarbons after purging operations

Assessment

End of course assessment with an 100% pass mark.

System Requirements

• Internet access - users will need a device with a web browser and internet connection

• System - runs on computers, tablets and mobile devices using Windows 7 and above and MAC OS devices running IOS 11 and above

• Browsers - Edge, Chrome, Firefox and Safari

• Minimum browser size – none

• Audio – requires device speaker or headphones

Accreditation

This course is CPD accredited. Established in 1996, The CPD Certification Service is the largest and leading independent CPD accreditation organisation working across all industry sectors. www.cpuk.co.uk

This course is OPITO accredited. OPITO is the global, not-for-profit, skills body for the energy industry and has been setting standards since 1991 to help improve workforce safety and competence. www.opito.com

Recommended Courses

Reviews

Insights & News

OPITO’s Authorised Gas Tester (AGT) accreditation is valid for three years

Short guide on how to take a photo of yourself (selfie) holding a photo ID for identity verification

At Mintra, we're so much more than just a team—we're a force driving innovation and excellence in maritime training across Europe.

We’re excited to be taking the stage at one of Europe’s leading showcases of organisational learning.

We are delighted to share the exciting news that our People and Culture team has been shortlisted for the prestigious cHeRries Awards!